Dyno Bench Technical Data

|

Item

|

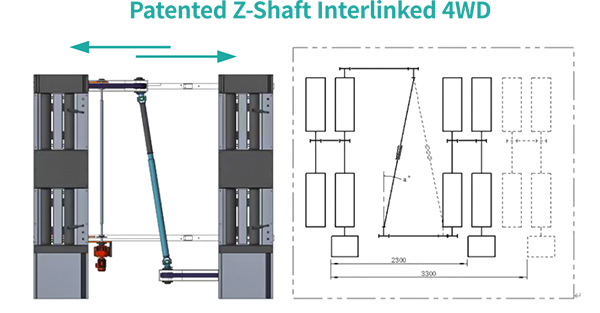

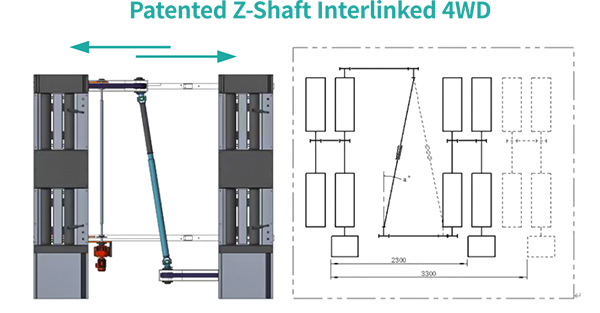

4WD EV Dyno(Z-Shaft Linked)

|

Heavy-duty chassis Dyno

|

|

Maximum carrying vehicle mass

|

5000kg

|

-

|

|

Maximum bearing axle mass

|

3000kg

|

13000kg

|

|

Maximum absorption driving force

|

0〜6000N×2

|

0-10000 N

|

|

Max. test speed

|

130 km/h

|

130 km/h

|

|

Roller diamete

|

Ф216mm

|

Ф373mm

|

|

Roller length

|

1000mm

|

1050mm

|

|

Inside wheel thread

|

700mm

|

900mm

|

|

Outer wheel thread

|

2700mm

|

2900mm

|

|

Minimum vehicle wheelbase

|

2300mm

|

-

|

|

Maximum vehicle wheelbase

|

3300mm

|

-

|

|

Eddy current rated power

|

160 kw x 2

|

700 kW(max absorbtion power)

|

|

Back drag motor power

|

7.5kW

|

11 kw(transducer control)

|

Software UI

|

|

|

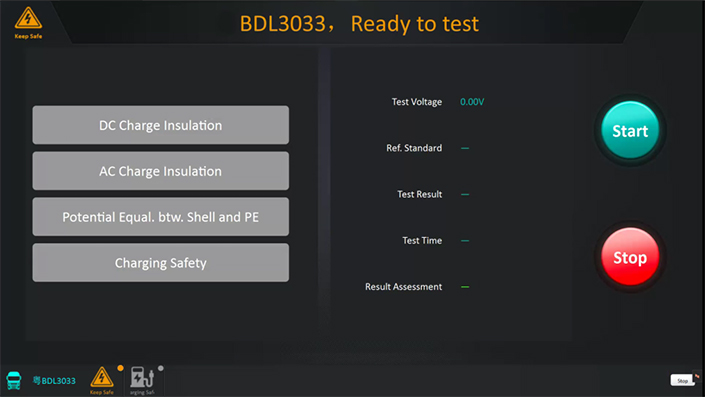

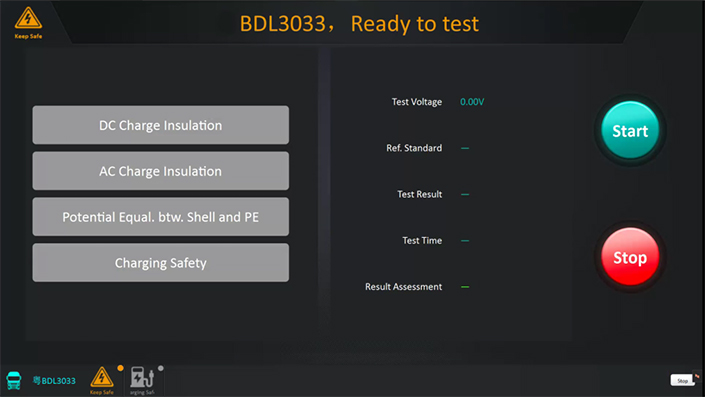

Dis-charging/Charging Test Software

|

Dis-charging Test Interface

|

|

|

|

Charging Test Interface

|

EV Test Operation Info. System

|

Why 4WD Synchronized

Most of the 2WD EVs have high-accuracy wheel traction control. However, if the four wheels are not moving at the same speed, power take-off of the EV could be limited or suppressed.

|

|

For All-Wheel Drive(AWD) EV, the front wheels and rear wheels are usually powered by two different motors with different power grades. As a result, the front wheels and the rear wheels will not have the same speed during a regular DYNO test.

|

|

To address this issue, we must use the interlinked 4WD Dynamometer for a perfect simulation of the synchronous operation of wheels during testing.

|

EV Dis-charging Test Functions

|

Discharging Simulation

|

|

BMS Monitoring and

Driving Capacity test

|

|

EV Output Power and

Electric Regenerative

Braking System Test (Optional)

|

|

4WD Cycle Running at 0-130km/h on

the Dyno chassis for the Battery

Discharge Simulation.

|

Real-time monitoring of EV's driving state during

the Dyno test (via EV-OBD or Dashboard). It is

also capable of testing the stability of an EV's

driving under specified conditions.

|

EV output power test is conducted

under a synchronous 4WD running

condition.

Comparison of drag power test for

ERBS of EV during its cruising cycle

(optional).

|

EV TEST CUSTOMER CASES